Enhancing Longevity with Engineered GRP Grating Products

In modern industrial applications, the demand for durable, lightweight, and low-maintenance flooring solutions is higher than ever. Traditional materials like steel and timber have long been relied upon, but they often fall short when it comes to resistance against corrosion, chemicals, and extreme weather. This is where GRP Grating has emerged as a revolutionary solution. Engineered GRP Grating products offer a unique combination of strength, longevity, and safety, making them the go-to choice for industries ranging from marine and utilities to construction and manufacturing.

This comprehensive article will explore how GRP Grating enhances industrial longevity, its key benefits, common applications, long-term cost advantages, and environmental impact. By understanding the value of these engineered solutions, industries can make informed choices for safer, more resilient infrastructure.

What is GRP Grating?

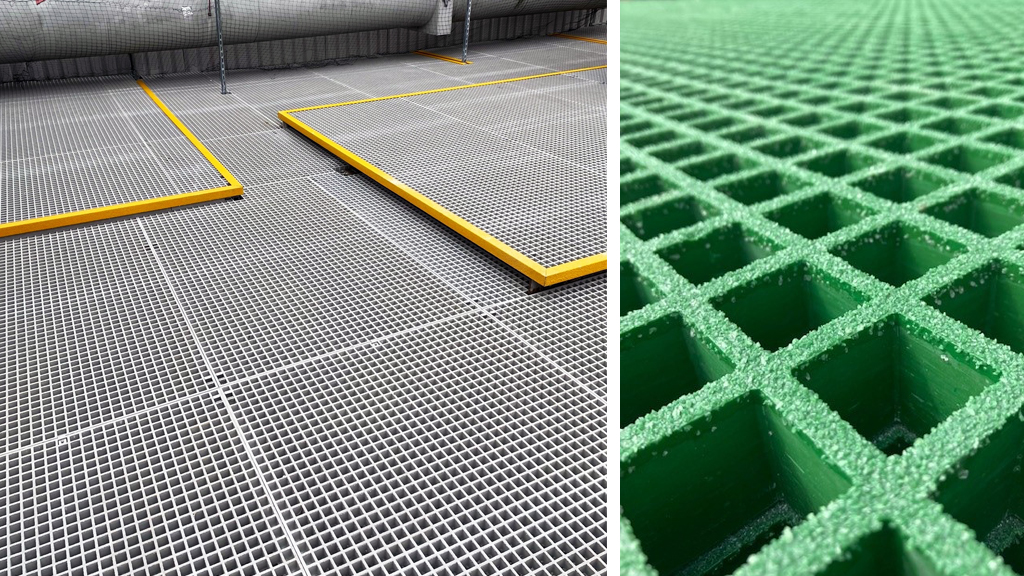

GRP Grating (Glass Reinforced Plastic Grating) is a composite material made by combining high-strength glass fibers with thermosetting resins. The fibers provide structural strength, while the resin binds them together, producing a lightweight yet extremely durable product. The result is a grating that is resistant to corrosion, chemicals, and fire, making it ideal for challenging industrial environments.

Types of GRP Grating

There are two primary types of engineered GRP Grating, each designed to meet specific industrial needs:

- Moulded GRP Gratings Moulded gratings are produced by casting resin and glass fibers in a mold, resulting in a strong, rigid structure. These are particularly suitable for environments with frequent chemical exposure or high moisture levels. Moulded GRP Grating is commonly used in wastewater treatment plants, chemical facilities, and marine environments.

- Pultruded GRP Gratings Pultruded gratings are manufactured through a continuous process where fibers are pulled through a resin bath and cured. This method produces gratings with higher strength, stiffness, and load-bearing capacity, making them ideal for long-span applications such as elevated platforms, walkways, and heavy-duty industrial flooring.

Both types share common advantages: they are fire-retardant, non-conductive, lightweight, and require minimal maintenance. These characteristics make GRP Grating an increasingly popular alternative to traditional steel or timber systems.

Key Benefits of GRP Grating

Engineered GRP Grating offers a range of advantages that traditional materials cannot match. These benefits contribute directly to the longevity and efficiency of industrial infrastructure.

1. Corrosion Resistance

One of the most significant advantages of GRP Grating is its inherent resistance to corrosion. Unlike steel, which rusts when exposed to water, chemicals, or salt, GRP remains unaffected by these environmental factors. This makes it ideal for:

- Marine environments (jetties, docks, offshore platforms)

- Water and wastewater treatment plants

- Chemical processing facilities

Benefits of corrosion resistance include:

- Extended lifespan, often exceeding 20 years

- Reduced maintenance and repair costs

- No need for additional coatings or protective treatments

By avoiding rust and chemical degradation, GRP Grating ensures infrastructure remains safe and reliable for decades.

2. Lightweight Yet Strong

Despite being lighter than steel, GRP Grating maintains exceptional strength and load-bearing capacity. This characteristic simplifies installation and reduces labor costs. Some advantages include:

- Easier handling and transportation, especially in remote locations

- No need for heavy lifting machinery

- Safer working conditions during installation

Lightweight yet strong gratings make GRP Grating particularly suitable for elevated platforms, stairs, and access walkways where weight limitations are a concern.

3. Slip Resistance

Safety is a primary concern in industrial environments. Many GRP Grating products feature an integrated quartz grit surface, providing superior anti-slip performance, even in wet, oily, or contaminated conditions. The benefits include:

- Enhanced site safety

- Compliance with occupational health and safety regulations

- Reduced workplace accidents and downtime

By reducing slips and falls, GRP Grating not only protects workers but also contributes to long-term operational efficiency.

4. Fire Retardancy and Non-Conductivity

Industrial applications often involve electrical installations or exposure to flammable materials. Engineered GRP Grating can be manufactured with fire-retardant resins and is naturally non-conductive. Benefits include:

- Lower risk of fire-related accidents

- Safer environments for workers in electrical installations or offshore platforms

- Compliance with fire safety standards

This combination of properties makes GRP Grating a safe choice for both onshore and offshore industrial applications.

Applications Across Industries

The versatility of GRP Grating means it is suitable for a wide range of industries. Its unique properties allow engineers and designers to implement it in challenging environments without compromising on safety or durability.

Construction and Infrastructure

In construction, GRP Grating is commonly used for:

- Walkways and catwalks

- Maintenance platforms

- Stair treads and ramps

Its lightweight nature reduces structural load, while its corrosion resistance ensures long-term performance in outdoor and high-moisture environments.

Water and Utilities

Water treatment facilities, pumping stations, and sewage plants benefit from GRP Grating due to its chemical and moisture resistance. Applications include:

- Platforms and walkways above treatment tanks

- Access covers for pumping systems

- Drainage grating in wet environments

Marine and Offshore

Saltwater and marine conditions accelerate corrosion in traditional materials. GRP Grating is ideal for:

- Jetties and piers

- Offshore oil and gas platforms

- Pontoons and boat docks

Its lightweight, anti-slip, and corrosion-resistant properties make it perfect for maritime environments.

Rail and Transport

GRP Grating is increasingly used in rail and transport applications for:

- Trackside walkways

- Station maintenance areas

- Elevated platforms

Its durability, lightweight structure, and safety features ensure long-term functionality and compliance with transportation safety standards.

Chemical and Manufacturing

Chemical plants and manufacturing facilities require materials that withstand spills, heavy traffic, and extreme conditions. GRP Grating excels in these environments, offering:

- Chemical resistance for acids, alkalis, and oils

- High load-bearing capacity for equipment access

- Minimal maintenance, even under heavy usage

Long-Term Cost Efficiency

While the initial cost of GRP Grating may be slightly higher than timber or steel alternatives, the total cost of ownership is significantly lower. Key factors contributing to long-term cost efficiency include:

- No corrosion, eliminating repainting or galvanizing expenses

- Minimal maintenance requirements

- Longevity exceeding 20 years, reducing replacement frequency

- Easier installation, reducing labor costs

For industries focused on balancing performance, safety, and budget, GRP Grating is an excellent investment.

Environmental Advantages

Sustainability is becoming a crucial consideration for modern industries. Engineered GRP Grating contributes to environmentally responsible practices through:

- Long lifespan, reducing material consumption and waste

- Low maintenance, minimizing harmful chemical coatings

- Recyclability at the end of its life cycle

- Reduced emissions due to lighter weight during transport and installation

By choosing GRP Grating, companies can enhance operational efficiency while supporting sustainable infrastructure development.

FAQs About GRP Grating

What makes GRP Grating better than steel or timber?

GRP Grating offers a combination of corrosion resistance, lightweight strength, non-conductivity, and fire retardancy, outperforming steel and timber in harsh industrial environments.

Can GRP Grating support heavy loads?

Yes. Pultruded GRP Grating is engineered for high load-bearing applications. It can be customized to meet specific structural requirements for elevated platforms and industrial walkways.

Is GRP Grating easy to install and maintain?

Absolutely. GRP Grating is lightweight, easy to cut on-site without specialized tools, and requires minimal maintenance, unlike steel, which may need coatings, galvanizing, or welding.

Conclusion

Engineered GRP Grating products are transforming industrial infrastructure by combining durability, safety, and cost-efficiency. From marine and chemical plants to construction and transport, industries are adopting GRP gratings for their long-term value and performance.

With advantages like corrosion resistance, fire retardancy, slip resistance, and environmental sustainability, GRP Grating is the smart choice for businesses aiming to enhance longevity and ensure worker safety.

For high-quality, UK-manufactured GRP Grating solutions backed by decades of expertise, industries can rely on engineered products that truly stand the test of time. Ready for more? Visit our homepage for deeper content and new releases.