Understanding Mobile Hydraulic Services

What Are Mobile Hydraulic Services?

Mobile hydraulic services encompass the maintenance, repair, and troubleshooting of hydraulic systems directly at their operational sites. This convenience allows operators to minimize downtime, enhance productivity, and address urgent hydraulic issues without needing transportation to a fixed service location. These services generally include fluid changes, system diagnostics, parts replacement, and repair work, which are crucial for industries relying heavily on hydraulic machinery. Utilizing mobile hydraulic services can significantly optimize operations and extend the lifespan of hydraulic systems.

Key Components of Hydraulic Systems

Hydraulic systems operate based on the principles of fluid mechanics to transfer power through hydraulic fluids. The primary components include:

- Hydraulic Fluid: This fluid transmits power and lubricates components. Its quality and type significantly influence system performance.

- Actuators: These convert hydraulic energy into mechanical energy, commonly found in cylinders and hydraulic motors.

- Pumps: Hydraulic pumps generate flow, providing the necessary pressure for fluid movement through the system.

- Valves: Valves control fluid flow and pressure, ensuring system safety and functionality. They come in various types, including directional, pressure, and flow control valves.

- Reservoir: This is where hydraulic fluid is stored, allowing for heat dissipation and settling of particulate contaminants.

Importance of Proper Maintenance

Regular maintenance of hydraulic systems is critical to prevent unexpected failures and maintain efficiency. Neglecting these services can lead to significant issues, including reduced performance, higher operational costs, and even catastrophic system failures. By implementing a consistent maintenance schedule, operators can ensure optimal performance and prolong the operational lifespan of their hydraulic equipment.

Common Issues in Mobile Hydraulic Systems

Identifying Hydraulic System Failures

Recognizing the early signs of hydraulic system failures can help mitigate extensive damage and costly repairs. Common indicators include:

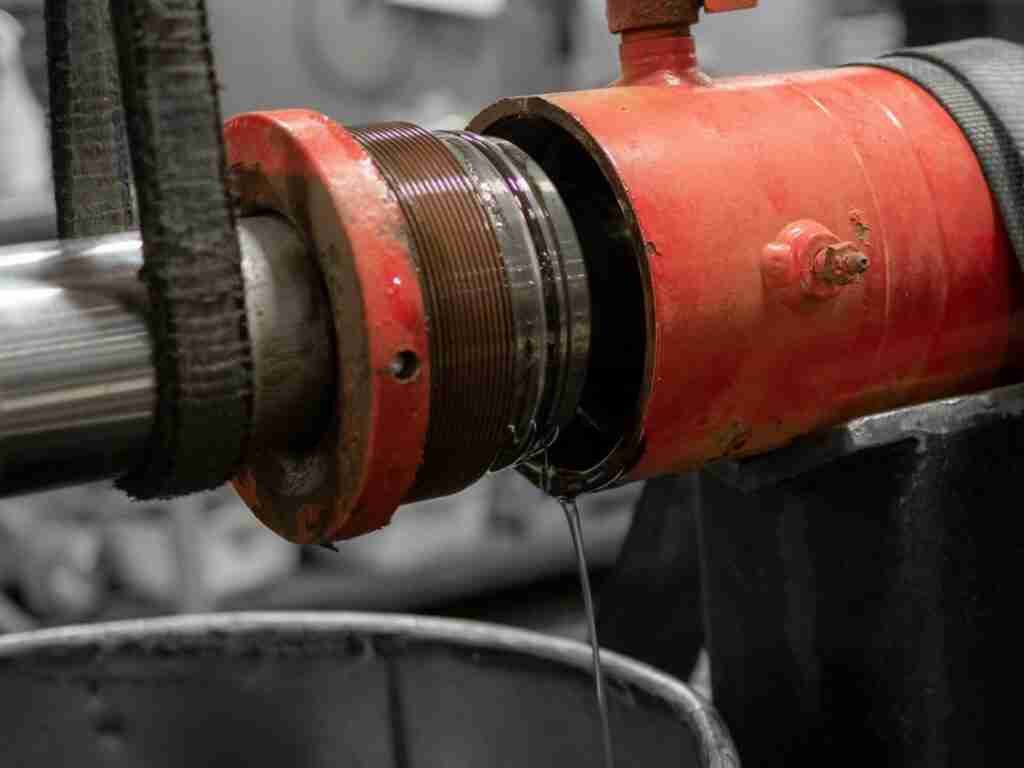

- Fluid Leaks: Visible fluid leaks can indicate a failure in seals or hoses, leading to pressure drops and potential system malfunction.

- Unusual Noises: Grinding or whining sounds often signal problems with hydraulic pumps or actuators.

- Decreased Performance: A system that exhibits sluggish response or reduced power output may require immediate attention.

- Inconsistent Operation: Erratic movements of hydraulic components can signify internal damage or air presence in the system.

Consequences of Ignoring Repairs

Ignoring hydraulic system issues can result in various negative outcomes, including:

- Increased Downtime: Machinery breakdowns lead to operational delays, affecting productivity and profitability.

- Higher Repair Costs: Minor issues can escalate into significant problems requiring extensive repairs if not addressed promptly.

- Injuries: Hydraulic systems under stress can pose safety risks to operators and nearby personnel.

Preventive Measures for Common Problems

To mitigate common hydraulic issues, consider implementing these preventive strategies:

- Regular Inspections: Schedule routine assessments to identify potential issues before they escalate.

- Fluid Testing: Regularly test hydraulic fluids for contaminants or degradation to ensure optimal system function.

- Filter Changes: Change hydraulic filters according to manufacturer recommendations to maintain fluid cleanliness.

Best Practices for Hydraulic Services

Scheduled Maintenance: Why It Matters

Regular maintenance helps ensure hydraulic systems are functioning at peak efficiency. Ideally, maintenance should occur every three to six months, depending on usage and operating conditions. Scheduled maintenance can include:

- Fluid replacement and analysis.

- Inspection and replacement of wear parts.

- Tightening of connections and checking hose integrity.

Tools and Equipment for Hydraulic Services

Using the right tools is essential for effective hydraulic services. Essential tools and equipment include:

- Pressure Gauges: These help monitor system pressure and detect anomalies early.

- Hydraulic Jacks: Useful for lifting machinery during inspections or repairs.

- Leak Detection Equipment: This aids in identifying faulty seals and fittings.

- Fluid Analysis Kits: These kits help assess the quality of hydraulic fluids.

Safety Precautions to Consider

Working with hydraulic systems presents risks; thus, adhering to safety protocols is paramount. Key safety precautions include:

- Always wear personal protective equipment (PPE), such as gloves and goggles.

- Ensure systems are depressurized before performing maintenance.

- Keep work areas clean to avoid accidents from spilled fluids.

Choosing the Right Service Provider

Criteria for Selecting Hydraulic Technicians

Choosing a qualified hydraulic technician is critical for effective service delivery. Look for technicians who possess the following:

- Certification: Opt for certified professionals who have undergone training in hydraulic systems.

- Technical Skills: A deep understanding of complex hydraulic systems is necessary for efficient troubleshooting and repair.

- Adaptability: Technicians should be capable of adapting services based on specific equipment needs.

Evaluating Experience and Expertise

Experience can significantly impact the quality of service provided. When evaluating potential service providers, consider:

- Years in Business: A provider with substantial experience is more likely to handle a variety of hydraulic systems.

- Specialized Knowledge: Select a provider who specializes in the types of hydraulic systems you utilize.

Importance of Customer Reviews and Testimonials

Customer feedback can provide valuable insights into the reliability and quality of service offered by hydraulic service providers. Look for:

- Consistent Positive Feedback: Patterns in reviews suggest reliability and service quality.

- Responsive Customer Service: Providers that address concerns and queries promptly often display professionalism and quality service.

FAQs About Mobile Hydraulic Services

What is included in mobile hydraulic services?

Mobile hydraulic services typically include maintenance, repair, and troubleshooting of hydraulic systems on-site.

How often should I schedule maintenance?

Maintenance should be conducted at regular intervals, ideally every 3 to 6 months, depending on usage.

What are common signs of hydraulic system issues?

Signs include leaking fluids, unusual noises, decreased performance, and inconsistent operation of machinery.

Can mobile hydraulic services improve equipment lifespan?

Yes, regular services help maintain efficiency and reduce wear, ultimately extending the lifespan of equipment.

How can I find a reliable hydraulic service provider?

Research local technicians, check reviews, and ask for referrals from trusted sources to ensure reliability.